In the manufacturing industry, Value Engineering is a term that is familiar and important but not always achievable, easy, or often utilized. Simply put, the primary focus of Value Engineering is assuring that the greatest functionality is delivered for the least cost or expense, in order to maximize value. When a manufacturing company can provide good Value Engineering to a product or service, the reward can be triple-fold with extensive savings on materials and material waste, as well as service and labor costs.

Here is an example:

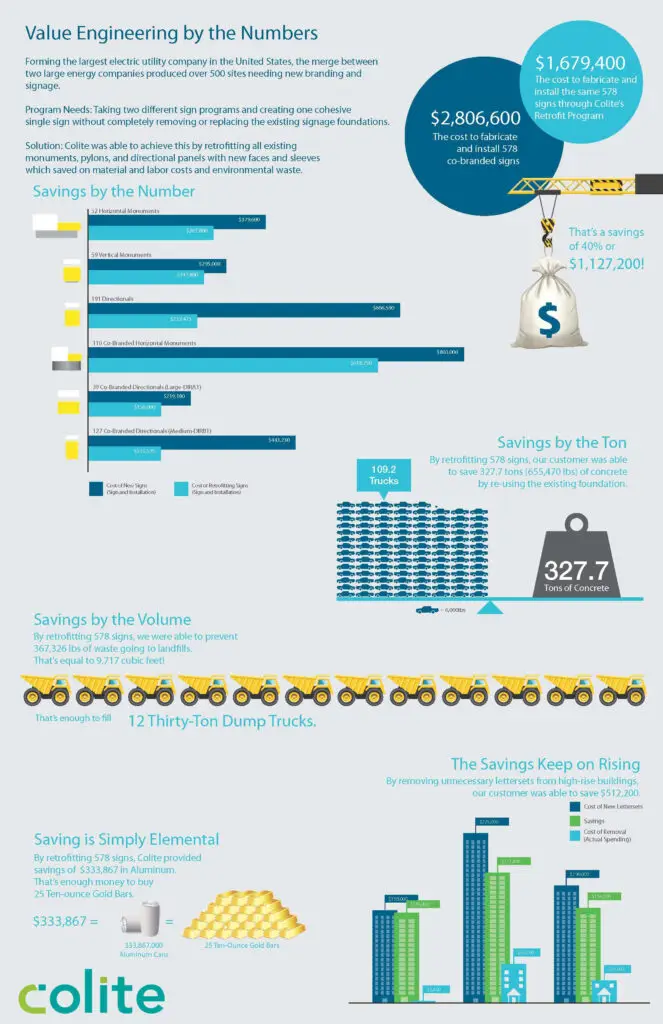

Having experienced brand conversions before, our client was prepared and knowledgeable on the costs that are incurred with large, multi-location signage programs. With their combined knowledge and experience in large rebranding programs, our client worked with Colite to develop a signage program focused around specific environmental and cost savings.

The Program:

Our client’s new portfolio would include over 500 sites throughout the Southeast region which would all need new signage with their new brand. Besides the volume of sites, the scope of work included a challenge of taking two different sign programs and creating one cohesive single sign without completely removing or replacing the existing foundations for over 500 monuments and directional signs.

How it’s done:

When a large corporation begins a rebranding program of any kind there are definite ways to save on cost, labor, and materials from the beginning. Here are a few ways Colite has found this can be done:

- Trusting your provider: As a previous signage provider for our client, Colite was familiar with their current signage program and was able to propose an easy way to retrofit their current signage.

- Preliminary Program Insight: Colite was aware of the signage quantity and implementation timeline from an early stage, therefore, we were able to order and plan for bulk materials and production.

- Surveying and Planning: With over 500 sites, Colite began surveying immediately to identify any special or custom sites which needed additional coordination or materials to successfully install signage.

- Designing to Save: Retrofitting the clients existing signage saved considerably on service costs of removing the old signage, and additional savings on material and labor costs by not having to install new foundations, resulting in cost savings of at least 35% over the entire program.

Successful Completion:

Colite was instrumental in saving the client over $1,000,000 in material and labor costs, as well as, greatly reducing environmental waste throughout every stage of the program which can definitely be attributed to Value Engineering.