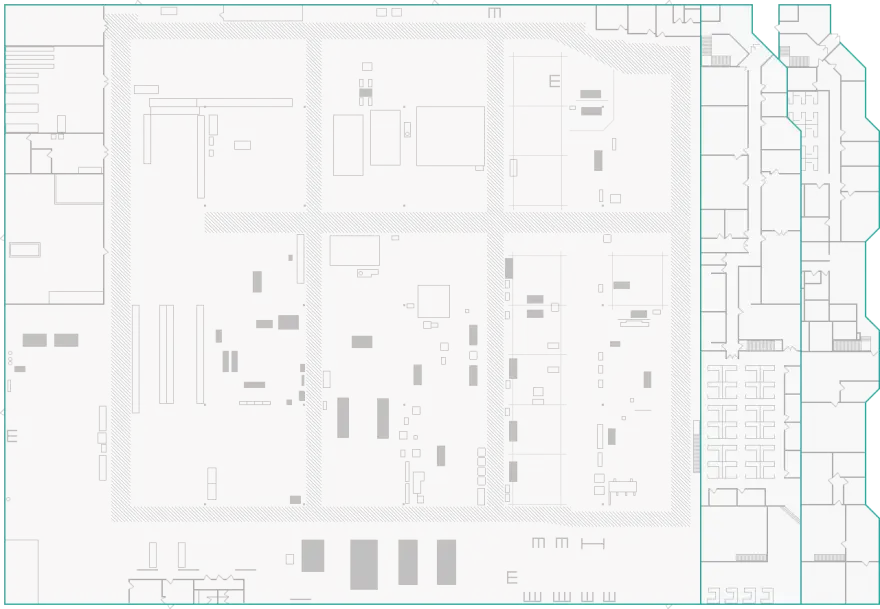

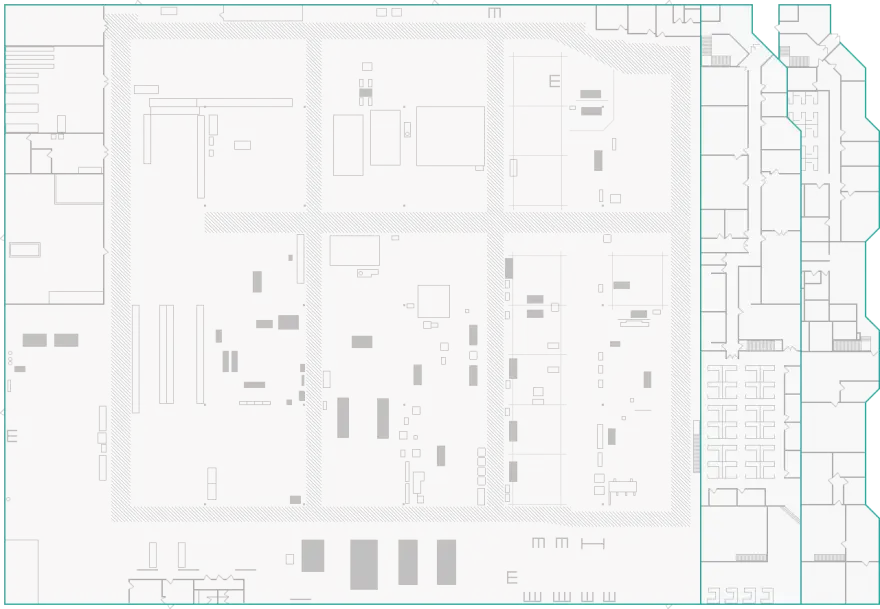

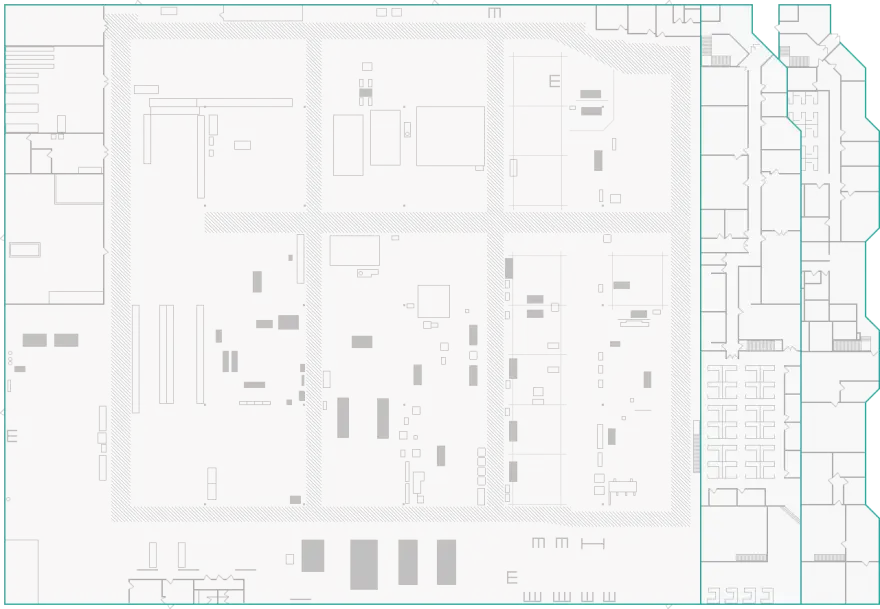

Serving clients worldwide from our 133,000 square foot manufacturing hub in Columbia, South Carolina, we’ve designed our facility with efficiency in mind. The organized layout optimizes our workflow, and our in-house manufacturing capabilities translate to significant advantages for our clients. From faster turnaround times and precise execution to uncompromised quality control, our streamlined process ensures the integrity of your signage program and delivers exceptional results.

Serving clients worldwide from our 133,000 square foot manufacturing hub in Columbia, South Carolina, we’ve designed our facility with efficiency in mind. The organized layout optimizes our workflow, and our in-house manufacturing capabilities translate to significant advantages for our clients. From faster turnaround times and precise execution to uncompromised quality control, our streamlined process ensures the integrity of your signage program and delivers exceptional results.

Click the hotspots to take a tour of our facility.

Shipping, Building, Packing & Storage

We are committed to continually reducing our impact on the environment and encouraging our customers, suppliers and other stakeholders to do the same.

Project Management

Good communication is the key to success in any project. When you’re manufacturing and installing complex signage programs in multiple countries, you have to be on top of every detail.

Graphics & Vinyl Department

Our Graphics and Vinyl department manages your project’s design files and engineered drawings for printing and application on a range of materials with a wide variety of advanced equipment.

Large-Format Printing

Our large-format printing capabilities allow us to print directly onto a variety of materials and serves as an integral part of our operation. With our large-scale printing, we’re able to deliver perfectly-matched colors, impeccable detail, and museum-quality prints on even the largest sheets of material.

Signature LED Room

Our Signature LED room is where we showcase and evaluate our different letter sets, illumination options and more.

Design Department

Before the first sign is manufactured, our design team is at work – creating, modifying, or developing your brand. Attention to every detail ensures the consistency and integrity of your brand is maintained.

Electrical Area & UL Certification

We love to see your brand shine brightly – but before we flip the switch – we put each unit that we build through a series of rigorous electrical tests and certifications to ensure that your signage operates safely and reliably for years to come.

Signature LED Receiving & Testing (UL)

Signature LED products produce exceptionally vibrant illumination within an energy efficient, maintenance-free unit.

Waterjet Cutting

Our waterjet cutting technology utilizes an incredibly high-pressure jet of water to cut through virtually any material with laser-like precision. This enables us to bring intricate designs to life even on the most sensitive of materials, without enduring the high heat generated through other means of cutting.

Laser Cutting

Our laser cutting technology relies on a high-power laser to cut through non-metallic materials with pin-point precision. This technology also allows us to deliver multiple cuttings from a single piece of material, maximizing the resources we’re using while minimizing the waste generated through production.

CNC Machining

Our CNC Machining area is where your signage program’s designs and engineered drawings meet high-tech automation and production. With these massive routers, we’re able to marry our precise design work with the large-scale raw materials that go into a signage program.

Welding

Once materials have been machined and prepped for production, our expert team of welders and fabricators work to connect the dots and bring your signs to life as your project takes shape.

Fabrication Area

After the surveys, brand books and designs have been completed, it’s time for fabrication. Here, our skilled craftsman use the world’s most advanced manufacturing equipment to bend metal, carve resins, and turn raw materials into branded reality.

Prototype Review Area

From site assessment and planning to design, fabrication, and installation, we’re the one-stop shop trusted by the world’s most recognizable brands to meet all their signage needs.

Upper Management

Our employees are like family. Most have been with us for more than ten years. This helps us ensure quality down the line. Because when people care and take pride in the work they do, the product is always better.

Purchasing & Operations

Before we begin welding sheet metal or prepping paints, our experienced Purchasing and Operations team gets to work sourcing and securing the right materials and logistical workflow for your program’s exact specifications.

"The Zone" Media Center

When you have teams of creative people, you need plenty of creative spaces. “The Zone” Media Center is one of the areas where our teams gather to collaborate, pitch ideas and more.

Post Paint Curing and Finishing

After your project makes its way through paint, it will stop in our curing and finishing area where it will be fully inspected and detailed before eventually making its way to shipping.

Pre-Paint Prep

Before our fabricated signs can be painted, they’ve got to be prepped. This is where we grind, sand, and smooth the surfaces of our signage before giving it that custom color and shine.

Paint Booths

With three automotive-grade paint booths and a high-end paint color matching system, our expert paint team is able to achieve incredible results.

Click the hotspots to take a tour of our facility.

Shipping, Building, Packing & Storage

We are committed to continually reducing our impact on the environment and encouraging our customers, suppliers and other stakeholders to do the same.

Project Management

Good communication is the key to success in any project. When you’re manufacturing and installing complex signage programs in multiple countries, you have to be on top of every detail.

Graphics & Vinyl Department

Our Graphics and Vinyl department manages your project’s design files and engineered drawings for printing and application on a range of materials with a wide variety of advanced equipment.

Large-Format Printing

Our large-format printing capabilities allow us to print directly onto a variety of materials and serves as an integral part of our operation. With our large-scale printing, we’re able to deliver perfectly-matched colors, impeccable detail, and museum-quality prints on even the largest sheets of material.

Signature LED Room

Our Signature LED room is where we showcase and evaluate our different letter sets, illumination options and more.

Design Department

Before the first sign is manufactured, our design team is at work – creating, modifying, or developing your brand. Attention to every detail ensures the consistency and integrity of your brand is maintained.

Electrical Area & UL Certification

We love to see your brand shine brightly – but before we flip the switch – we put each unit that we build through a series of rigorous electrical tests and certifications to ensure that your signage operates safely and reliably for years to come.

Signature LED Receiving & Testing (UL)

Signature LED products produce exceptionally vibrant illumination within an energy efficient, maintenance-free unit.

Waterjet Cutting

Our waterjet cutting technology utilizes an incredibly high-pressure jet of water to cut through virtually any material with laser-like precision. This enables us to bring intricate designs to life even on the most sensitive of materials, without enduring the high heat generated through other means of cutting.

Laser Cutting

Our laser cutting technology relies on a high-power laser to cut through non-metallic materials with pin-point precision. This technology also allows us to deliver multiple cuttings from a single piece of material, maximizing the resources we’re using while minimizing the waste generated through production.

CNC Machining

Our CNC Machining area is where your signage program’s designs and engineered drawings meet high-tech automation and production. With these massive routers, we’re able to marry our precise design work with the large-scale raw materials that go into a signage program.

Welding

Once materials have been machined and prepped for production, our expert team of welders and fabricators work to connect the dots and bring your signs to life as your project takes shape.

Fabrication Area

After the surveys, brand books and designs have been completed, it’s time for fabrication. Here, our skilled craftsman use the world’s most advanced manufacturing equipment to bend metal, carve resins, and turn raw materials into branded reality.

Prototype Review Area

From site assessment and planning to design, fabrication, and installation, we’re the one-stop shop trusted by the world’s most recognizable brands to meet all their signage needs.

Upper Management

Our employees are like family. Most have been with us for more than ten years. This helps us ensure quality down the line. Because when people care and take pride in the work they do, the product is always better.

Purchasing & Operations

Before we begin welding sheet metal or prepping paints, our experienced Purchasing and Operations team gets to work sourcing and securing the right materials and logistical workflow for your program’s exact specifications.

"The Zone" Media Center

When you have teams of creative people, you need plenty of creative spaces. “The Zone” Media Center is one of the areas where our teams gather to collaborate, pitch ideas and more.

Post Paint Curing and Finishing

After your project makes its way through paint, it will stop in our curing and finishing area where it will be fully inspected and detailed before eventually making its way to shipping.

Pre-Paint Prep

Before our fabricated signs can be painted, they’ve got to be prepped. This is where we grind, sand, and smooth the surfaces of our signage before giving it that custom color and shine.

Paint Booths

With three automotive-grade paint booths and a high-end paint color matching system, our expert paint team is able to achieve incredible results.

Click the hotspots to take a tour of our facility.

Shipping, Building, Packing & Storage

We are committed to continually reducing our impact on the environment and encouraging our customers, suppliers and other stakeholders to do the same.

Project Management

Good communication is the key to success in any project. When you’re manufacturing and installing complex signage programs in multiple countries, you have to be on top of every detail.

Graphics & Vinyl Department

Our Graphics and Vinyl department manages your project’s design files and engineered drawings for printing and application on a range of materials with a wide variety of advanced equipment.

Large-Format Printing

Our large-format printing capabilities allow us to print directly onto a variety of materials and serves as an integral part of our operation. With our large-scale printing, we’re able to deliver perfectly-matched colors, impeccable detail, and museum-quality prints on even the largest sheets of material.

Signature LED Room

Our Signature LED room is where we showcase and evaluate our different letter sets, illumination options and more.

Design Department

Before the first sign is manufactured, our design team is at work – creating, modifying, or developing your brand. Attention to every detail ensures the consistency and integrity of your brand is maintained.

Electrical Area & UL Certification

We love to see your brand shine brightly – but before we flip the switch – we put each unit that we build through a series of rigorous electrical tests and certifications to ensure that your signage operates safely and reliably for years to come.

Signature LED Receiving & Testing (UL)

Signature LED products produce exceptionally vibrant illumination within an energy efficient, maintenance-free unit.

Waterjet Cutting

Our waterjet cutting technology utilizes an incredibly high-pressure jet of water to cut through virtually any material with laser-like precision. This enables us to bring intricate designs to life even on the most sensitive of materials, without enduring the high heat generated through other means of cutting.

Laser Cutting

Our laser cutting technology relies on a high-power laser to cut through non-metallic materials with pin-point precision. This technology also allows us to deliver multiple cuttings from a single piece of material, maximizing the resources we’re using while minimizing the waste generated through production.

CNC Machining

Our CNC Machining area is where your signage program’s designs and engineered drawings meet high-tech automation and production. With these massive routers, we’re able to marry our precise design work with the large-scale raw materials that go into a signage program.

Welding

Once materials have been machined and prepped for production, our expert team of welders and fabricators work to connect the dots and bring your signs to life as your project takes shape.

Fabrication Area

After the surveys, brand books and designs have been completed, it’s time for fabrication. Here, our skilled craftsman use the world’s most advanced manufacturing equipment to bend metal, carve resins, and turn raw materials into branded reality.

Prototype Review Area

From site assessment and planning to design, fabrication, and installation, we’re the one-stop shop trusted by the world’s most recognizable brands to meet all their signage needs.

Upper Management

Our employees are like family. Most have been with us for more than ten years. This helps us ensure quality down the line. Because when people care and take pride in the work they do, the product is always better.

Purchasing & Operations

Before we begin welding sheet metal or prepping paints, our experienced Purchasing and Operations team gets to work sourcing and securing the right materials and logistical workflow for your program’s exact specifications.

"The Zone" Media Center

When you have teams of creative people, you need plenty of creative spaces. “The Zone” Media Center is one of the areas where our teams gather to collaborate, pitch ideas and more.

Post Paint Curing and Finishing

After your project makes its way through paint, it will stop in our curing and finishing area where it will be fully inspected and detailed before eventually making its way to shipping.

Pre-Paint Prep

Before our fabricated signs can be painted, they’ve got to be prepped. This is where we grind, sand, and smooth the surfaces of our signage before giving it that custom color and shine.

Paint Booths

With three automotive-grade paint booths and a high-end paint color matching system, our expert paint team is able to achieve incredible results.

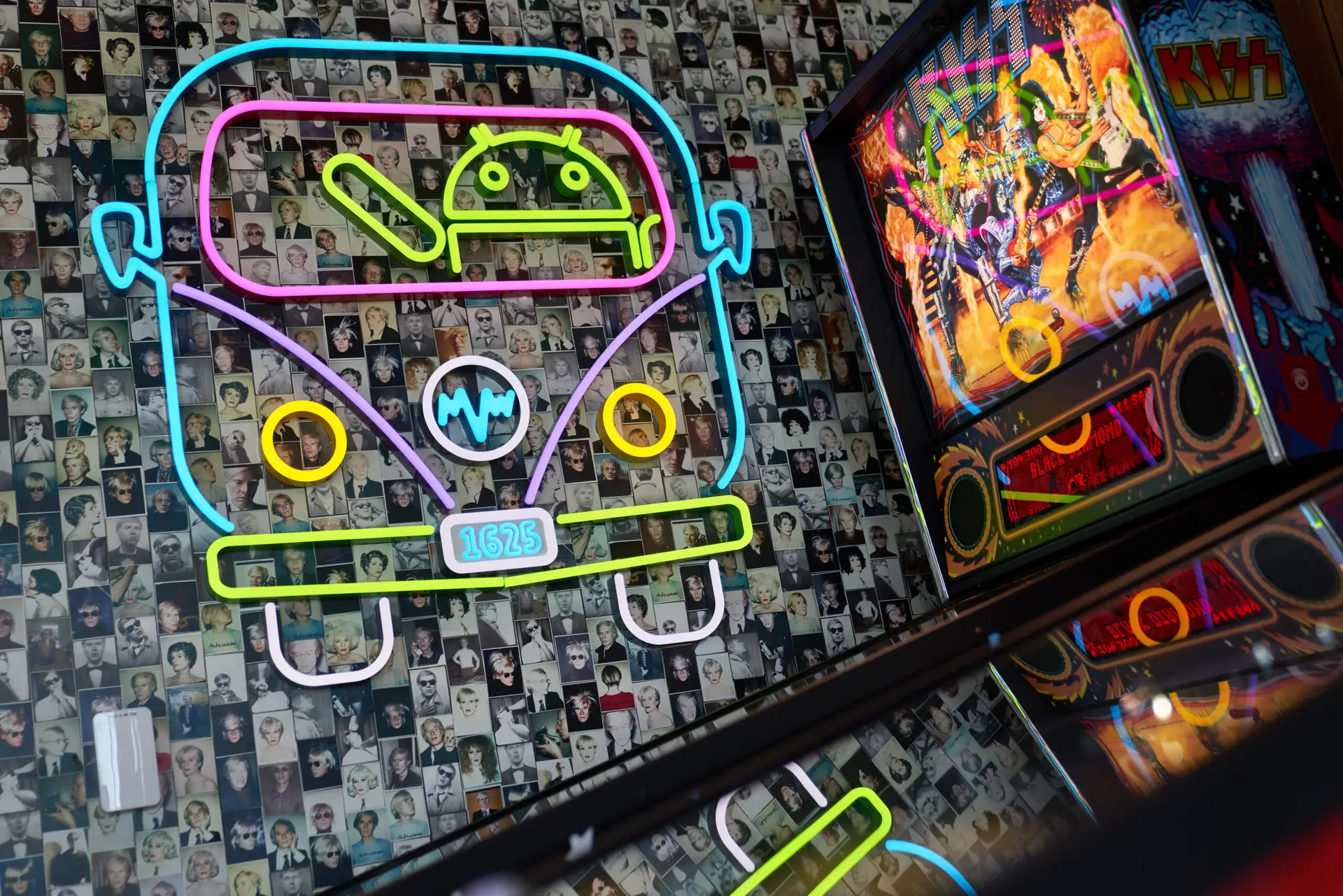

Every brand is unique, and your signage should reflect that. At Colite, we create custom signage solutions that represent your brand’s personality. Whether you need storefront displays, wayfinding systems, or interior signage, we work closely with you to ensure the design, materials, and installation align with your vision. From concept to completion, our team combines creativity and craftsmanship to deliver signage that reinforces your brand and makes a lasting impression.